How to Make an Ultralight Soda Can Alcohol Stove

We all aspire to hike lighter. Unfortunately, ultralight gear is expensive. Even standard camp stoves can run $50 and up, making alcohol stoves a viable alternative. Of the many reasons why someone would choose to carry an alcohol stove, two stick out: price and weight. The upfront cost of constructing an alcohol stove is minimal, and the stove itself is feather light.

Check out the video here, and detailed instructions can be found below.

If you choose to carry an alcohol stove, you need to consider the availability of denatured alcohol along your route, and the amount of fuel you will need to carry between resupplies. In my experience, thru-hikers often had to seek out auto-body or specialty shops in order to find the necessary fuel. When they did, they had to buy large containers, leaving significant amounts behind in town. This most likely undermined any cost savings they were hoping to make by building their own stove.

It is also important to remember that denatured alcohol is nasty stuff and is extremely flammable. One thru-hiker we met opened her pack at the end of a long day of hiking to find that her fuel container had failed and her gear was soaked in the stuff.

In addition, carrying another bottle of liquid, a pot stand, and wind screen, may negate any weight savings you may make over a store-bought canister stove.

If you do decide to carry a soda can alcohol stove, what do you need to make one? You guessed it, a can of soda—actually TWO cans of soda. Choose a flavor you enjoy so you’re not just pouring it down the drain.

Once you have two clean, empty aluminum cans and the tools listed below, you can follow the steps to construct your very own soda can alcohol stove.

Ultralight Soda Can Alcohol Stove

Weight: 0.45 ounces

Cost: less than $3

Time to construct: 20 – 60 minutes

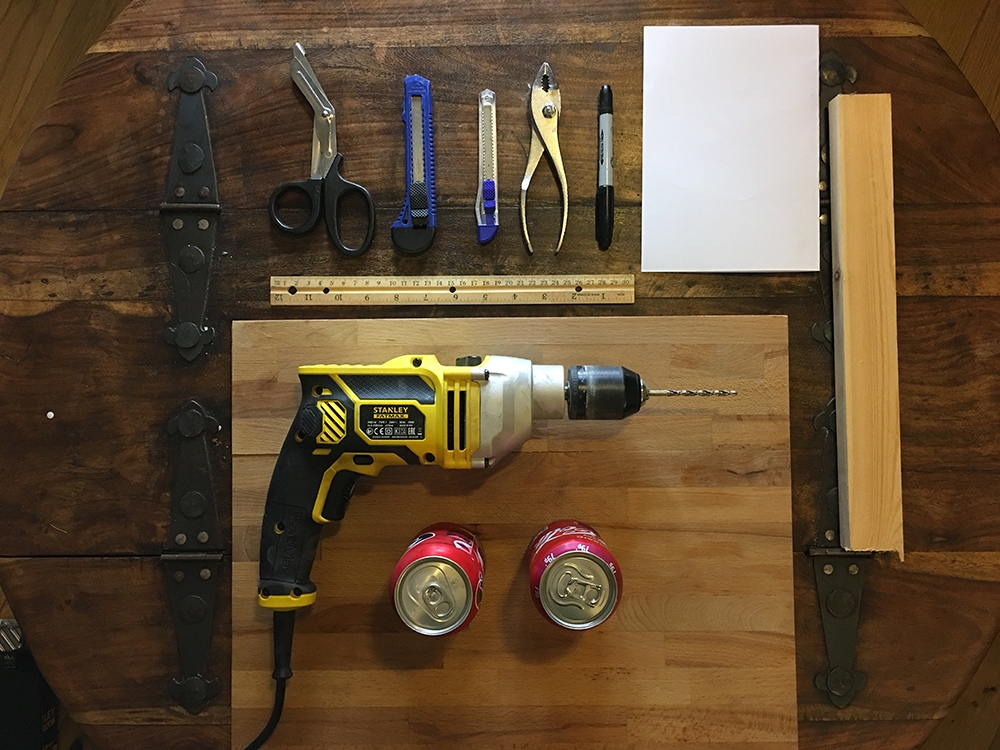

Tools Needed

- THREE cans of soda (Two clean and empty. One kept in the freezer until needed later, and remember to keep an eye on it so it doesn’t explode.)

- Ruler

- Scissors that you don’t mind getting dulled by cutting aluminum cans

- Two Stanley/X-Acto Knives (One large, one small)

- Pliers

- Sharpie

- One piece 8.5 x 11 paper

- Piece of narrow scrap wood (1″ x 2″)

- Drill with a small bit

- Durable work surface

Take care when using the tools and materials involved in constructing this stove!

Step 1: Cut the Cans

We need the bottom of TWO soda cans.

The first can is your stove base.

Using your ruler and Sharpie, measure 1 1/4 inches (37 cm ) from the tapered bottom of the can. Mark the can in several places so you can connect the dots and ensure accurate measurement.

There are a number of ways to cut an aluminum can. I prefer the “scoring” method.

Applying medium pressure, turn the soda can around against a fixed blade until the repeated scoring marks cut the can into two separate pieces.

Secure your the blade in a fixed position to avoid cutting the can in a spiral.

Resist the urge to saw or cut the can to avoid denting, warping or otherwise compromising the aluminum. Keep scoring it until you can easily break the can apart.

Set the pieces aside and move on to your second can.

The second can is your stove top.

Using your smaller X-Acto blade, score the inside rim of the base of the can. Go slowly, mindful that the metal is thicker here and will require a considerable amount of scoring before you cut all of the way through.

Once you have a hole in the bottom of your second can, mark and score and cut the same way you cut the first soda can.

At this point, you will have two of the three pieces required to construct your stove. You’ll notice that it is impossible to slide them together as they are currently the same diameter as one another. You will need to widen or spread the bottom can in order to accommodate the top of the stove. We will do this a bit later.

Before we proceed, let us consider why we are making a soda can stove in the first place? Why not just burn fuel in an open container like a tin can? The answer is that it is inefficient. This stove design has an inner wall that allows for the fuel to be held in a narrow cavity between the outer wall of the cans and the wide opening where we will pour the fuel. This allows for increased temperature, convection, and a modest amount of propulsion, making the stove more efficient in burning the fuel.

Step 2: Cutting the Inner Wall

The inner wall is the top of the first can.

The inner wall will fit perfectly inside your new stove. Using your Sharpie, ruler and piece of paper, measure a rectangle 7 1/4 inches (18 1/2 cm) x 2 1/4 inches (5 1/2 cm).

Mark two opposing perpendicular lines, each three-quarters of an inch from either end of the long side, half the length of the short side.

Make three notch marks spaced equidistant along the bottom of the template. Using scissors, cut the template from the paper.

Wrap your template around the remainder of one of your soda cans and trace the paper template onto your soda can.

You will notice that the template DOES NOT wrap all of the way around the can—this is important.

Carefully cut the aluminum can along the traced lines.

Step 3: Expanding the Stove Base

As mentioned earlier, the top and bottom cannot fit together as they are the same diameter. The base must be expanded in order for you to assemble the stove.

Retrieve the third soda from the freezer.

Using pliers, hold the stove base over a medium flame to warm the metal, mindful not to burn yourself.

Use the near-frozen soda to press into the warmed stove base. Apply firm even pressure to widen the can. Be aware that you are trapping a bubble of air between the cold soda and the warm base. Gently rock the can back and forth to allow the air to escape to avoid rupturing the base.

Press the can all the way to the bottom of the stove.

Step 4: Drilling Jet Holes in the Stove Top

Using the Sharpie, mark uniform dots around the rim of the stove top.

Using the drill, carefully make small holes on the marks.

Be sure to drill the holes in the top of the stove—the one with the open top—so you don’t get holes in the bottom of your stove.

Use a piece of fine sandpaper or a file to smooth the burrs and sharp bits from the three final pieces.

Step 5: Stove Assembly

Start with the inner wall. Curl the rectangle into a cylinder notching the slots together right to the edge.

With the notches at the bottom, place the inner wall cylinder in the base of your new stove.

The cylinder will fit perfectly on to the raised bump at the bottom of the base.

Slide the top into the base of the stove. Even after spreading the base wider, it is still a tight fit and needs patience to slot them together.

Once the top is in the base, and before you press it all of the way down, make sure to line up the inner wall and slot it into and behind the upper rim.

Slide the top all the way down to the bottom of the base, and you have yourself a stove.

Notes

You’ll notice that the opening at the top is same width as the height of your stove. If you choose to make another style of stove, keep this ratio in mind to ensure your stove is as efficient as possible.

Be careful when adding fuel to the wide opening of your stove. Do not overfill. Do not get it on your clothes or gear. Never ingest the fuel. Always set your stove on a stable surface before lighting it.

Let the stove warm up before using it. As it warms up, the jets will burn blue. A yellow flame will burn high.

A soda can stove is not the most stable for holding a pot, which may require a separate pot stand. Alcohol fuel will gather on the bottom of your pot, so allow it to burn off before setting it down anywhere.

This website contains affiliate links, which means The Trek may receive a percentage of any product or service you purchase using the links in the articles or advertisements. The buyer pays the same price as they would otherwise, and your purchase helps to support The Trek's ongoing goal to serve you quality backpacking advice and information. Thanks for your support!

To learn more, please visit the About This Site page.

Comments 13

That’s an excellent how-to.

Thanks for putting together this video.

Have you ever made an alcohol stove from materials more durable than aluminum?

I’ve thought of using a tuna can, or something similar, but I wouldn’t know how to deal with the opening, as it must be the same size as the stove is tall (something I did not know until now).

I have made cat food and tuna can stoves, but the aluminium soda stove is my favourite and is plenty durable (especially when you add the inner wall and set the top and bottom together). I’d bet you could beat it pretty bad before it would fail.

Happy Trails

I made mine from a tuna can with a cotton rag stuffed in. Poured some alcohol in and lit it. Set it inside a larger can with holes cut into the side so I have something to set the pot on. One big danger with these alcohol stoves is if you’re replenishing the fuel and pouring alcohol in and the flame is not all the way out you can be injured in the ensuing explosion. So pass your hand over the top first to feel if the flame is completely out. The flame from burning alcohol can be invisible. Also I can use the larger can for a twig stove.

Does this actually work any better than the stove I made using a cat food can? If so, please explain.

Thanks in advance.

I am not sure what cat food stove you have made, so I am at a disadvantage in trying to tell you the differences. But I’ll take a stab at an answer. Most cat food stoves I’ve seen are open bath designs, which rely on the back pressure from a pot set on top to create the propulsion you require. This stove has an inner wall creating its own pressure which is more versatile. Most cat food stoves are good for getting water to a boil, but not good for cooking on (as it will burn your food). This stove allows for simmering and cooking. Also the open bath on most cat food stoves means it’s burning more fuel than necessary – requiring you to carry more fuel.

Hope that helps. Like I said, I don’t know what stove you’ve constructed. There are lots of great designs out there – this is just one of them.

Happy Trails.

Yes, that inner wall added a lot of strength, I could see that in the video.

This is the first alky-stove design I’ve seen that used the inner wall. Most of the stoves I’ve looked it online I would not want to use — look weak.

On this design, do you have to place the pot on the stove to get it to work well, or could I place the pot on a lightweight stand and scootch the stove under it?

I recommend a pot stand. The stove is small in diameter, so unless you are using a small stove, it will be unstable. I would set the stove on a stable surface, light it, let it warm up allowing flames to turn blue, then move the stand and pot over it, as it will get quite hot, making scooting it under the pot very dangerous.

Hope that helps. Happy Trails.

If you’re going to make a soda can stove, look up Spiguyver on YouTube and follow his most recent Spiguyver Stove 2.0 updated design. One small soda can (7.5 oz) or small Starbucks can is all you need. Takes less than 10 minutes to make. Works great. No pot stand required. Mine weighs 6.8 grams.

And you can use yellow Heet, which is available at any Walmart, auto parts store, and many gas station convenience stores. 10 oz is less than $1.50. I usually boil 2 cups of water with about 1/2 oz of fuel. Sometimes it takes 3/4 oz. It depends on the season. Coffee/tea (12 oz) only takes a 1/2 oz of fuel.

When ever i put my pot it off i used mentanol